Automated Inhaler Tester

Accurate, repeatable and reproducible testing of pMDI’s

System Engineering, Control Software, Commissioning, Qualification

The world’s pharmaceutical industry is heavily regulated. This means that before a single inhaler can be sold, evidence must be collected and presented to show that the drug works, that the device delivers the drug to the patients’ lungs, and that each inhaler in each production batch meets performance specification.

These performance specifications are typically defined in the Device Functionality Profile (DFP) which describes the key functional aspects of the device, and the acceptance limits. This is an element of ISO 20072 which covers the verification requirements and test methods for aerosol drug delivery devices (ADDD’s).

This means that a inhalers need to be consistently and tested to a very high standard, throughout the product life cycle.

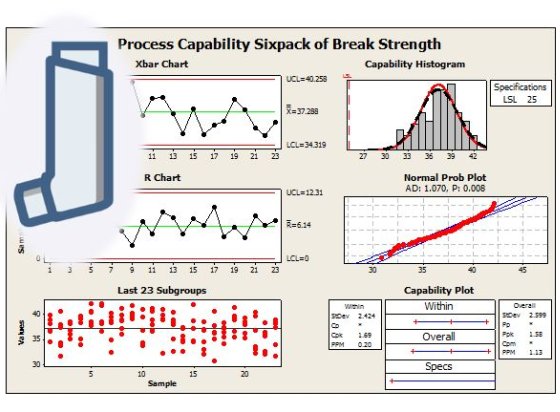

Unfortunately, accurately testing inhalers consistently is notoriously difficult to do, even with just small batch sizes. Variation in test results can come from a range of sources; some expected and acceptable, others unwelcome.

These might be due to variations in pre-conditioning, test conditions, analyst technique, component moulding and device assembly.

By automating inhaler testing, you can separate variations due to device or test method, increase confidence in results, and subsequently transfer test methods with greater ease, less training whilst maintaining conformance.

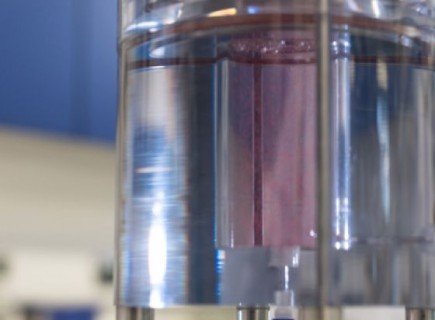

Cambridge Medtech Solutions have led the specification, design, development, installation and qualification to GAMP5 of a bespoke automated inhaler tester for pressurised metered dose inhalers (pMDIs).

“Automated testing is an effective in-process monitoring tool, which provides an improved level of accuracy and reproducibility, whilst achieving increased levels of throughput and capacity. Crucially, the released dose is also captured in a controlled manner. This makes automated testing a highly cost effective solution for us.”