System for Crystallisation of Active Pharmaceutical Ingredient (API)

IPSE GAMP5 Compliant

Validation Engineering

Challenge

Working with Huxley Bertram to support a global pharmaceutical company with the qualification of a bespoke pharmaceutical crystallisation system used in API manufacture.

Approach

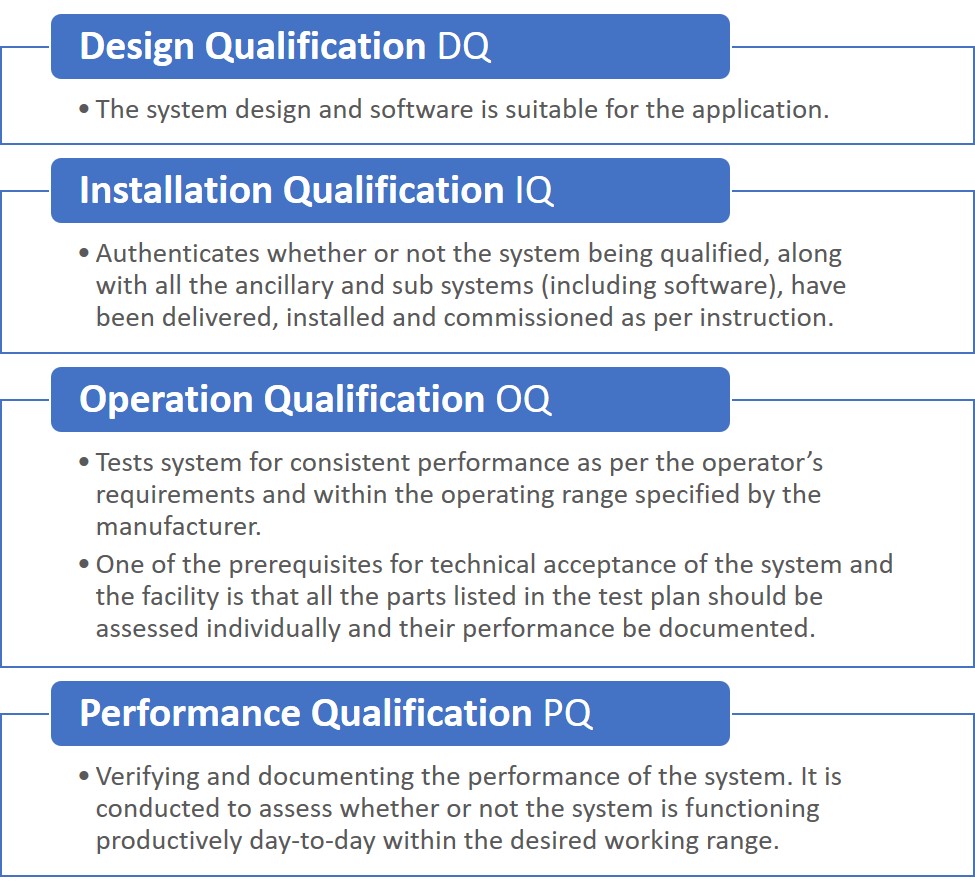

We worked with Huxley Bertram to prepare the Installation Qualification (IQ) and Operational Qualification (OQ) protocols for Factory Acceptance Tests (FAT) and Site Acceptance Tests (SAT), in order to commission the production unit.

Outcome

The unit has been commission and is successfully running at the production site.

Huxley Bertram were contracted to design, build, test and commission a bespoke pharmaceutical crystallisation system used in API manufacture.

The system incorporates liquid delivery and crystallisation at low temperatures. The unit included PLC based control connecting to the clients SCADA and delivering data to an electronic batch record system. The system is ISPE GAMP5 compliant.

Cambridge Medtech Solutions prepared the detailed Installation Qualification (IQ) and Operational Qualification (OQ) protocols for Factory Acceptance Tests (FAT) and Site Acceptance Tests (SAT).

The unit has been commission and is successfully running at the production site.