Lifetime Warranty Testing

Critical Infrastructure Monitoring Equipment

Reliability Engineering

Challenge

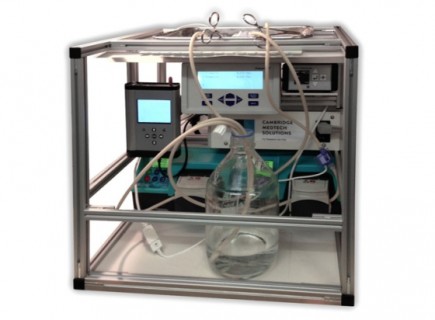

Our client supplies critical infrastructure monitoring equipment used in clinical environments, and they want to introduce a lifetime warranty for one of their flagship products. Offering such a guarantee for mission-critical equipment would not only differentiate their product in a competitive market but also reflect confidence in its long-term performance.

However, to justify this level of commitment, the client needed robust, data-driven insights into product reliability across its expected lifespan. While MEOST (Multiple Environment, Over-Stress Testing) had previously been used in early development stages to identify and mitigate failure modes (Stages 1–5), the current challenge was to design a structured test plan using MEOST Stages 6 and 7 to estimate product life at 0, 6, and 12 months using field-returned units.

The key objective was to simulate the combined effects of real-world stressors on these used samples, quantify degradation patterns, and develop predictive models that could validate claims of lifetime performance.

Approach

Our reliability engineers applied the disciplined, MEOST-based methodology, with a focus on Stages 6 and 7 (Life Testing and Warranty Estimation) building on the comprehensive failure mode insights already uncovered in prior development stages.

1. Data-Driven Sample Selection

We began by defining criteria for selecting representative field-returned units at the 0, 6, and 12-month marks. Devices were chosen from varying geographic locations and use profiles to account for environmental and operational variability. Each unit underwent an initial diagnostic to document wear levels and baseline performance metrics.

2. MEOST Stage 6 – Accelerated Life Testing Under Combined Stress

Using a test matrix grounded in known stressors (e.g. thermal cycling, vibration, electrical load, humidity, and contamination), we subjected each sample to accelerated life testing with multiple simultaneous overstress conditions. Crucially, these stress levels were increased just beyond expected field conditions – as prescribed by MEOST – but below the threshold of destruction, ensuring meaningful life prediction without catastrophic failure.

The goals of this stage were to:

- Capture performance degradation curves across timepoints

- Identify new failure mechanisms emerging from combined stress environments

- Establish failure thresholds in relation to real-world use

3. MEOST Stage 7 – Statistical Modelling and Life Estimation

Following testing, we applied statistical reliability modelling to extrapolate failure rates and performance decay curves across a theoretical full lifespan. Tools included Weibull and log-normal analyses, adjusted for MEOST-specific acceleration factors. This provided failure probability estimates across time intervals and stress combinations.

Data from each timepoint enabled:

- Trend analysis of degradation over time

- Correlation of observed failures with prior MEOST-identified modes

- Confidence interval estimates for “no failure” operation scenarios

4. Alignment with Lifetime Warranty Strategy

Results were mapped against warranty risk tolerance levels, allowing the client to define a quantitative reliability benchmark that could credibly underpin a future lifetime warranty offering. Additionally, outputs fed directly into their product quality surveillance system to inform post-market monitoring.

Outcome

The test plan, developed and executed through the MEOST framework, provided a validated, evidence-based understanding of product life and failure behaviour under real-world and accelerated conditions. Tangible outcomes included:

- Life prediction curves for each tested timepoint, supporting robust forecasting of long-term product performance,

- Zero unexpected failure modes beyond those already identified in earlier MEOST stages; affirming product maturity,

- Quantifiable reliability thresholds, giving the client the confidence to proceed toward a phased launch of their lifetime warranty offering,

- Enhanced field reliability strategy, with test plan architecture now integrated into ongoing quality assurance programs.

This case demonstrates how structured overstress methodologies – when applied rigorously at later stages of the product lifecycle – can provide the confidence needed to make bold, market-defining warranty commitments.