Finger Pulse Oximeters

Robustness Comparability Study

Reliability Engineering, MEOST, Weibull Analysis

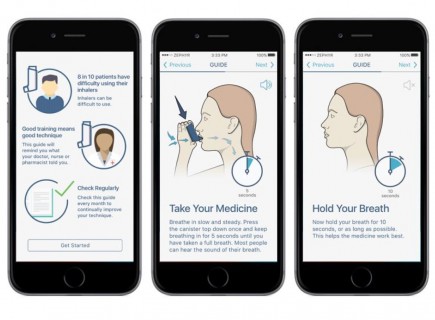

Finger Pulse Oximeters are simple, non-invasive medical devices for measuring a user’s oxygen saturation (SpO2). It is a measure of how much oxygen the haemoglobin (blood) is carrying round the body, as a percentage of the maximum amount it could carry.

For most people, oxygen saturation should always be above 95%, but may be lower in those with a cyanotic congenital heart disease or a long-standing respiratory disease. They are especially helpful for patients with Chronic Obstructive Pulmonary Disease (COPD) including Emphysema, Asthma and Bronchitis.

Pulse Oximeters vary tremendously in design, size, appearance and price, and Finger Pulse Oximeters are generally the smallest and cheapest available. Fundamentally, all of them perform the same basic function of displaying the oxygen saturation and pulse rate measurements.

They have effectively become a consumable healthcare product, and are now a popular purchase for home use.

However, even after meticulous detailed design, engineering analysis, material selection and specification verification testing, a product can still fail prematurely. This happens when the stresses of everyday use – for example, temperature, humidity, vibration, shock, electrical overload and crush – combine in unexpected ways and create new interactions.

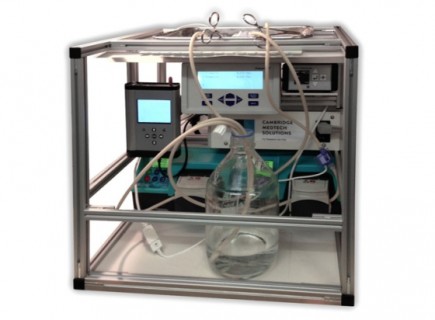

Cambridge Medtech Solutions was asked to compare the robustness of a range of competitive Finger Pulse Oximeters, and to identify the failure modes.

We applied the Multiple Environment Over Stress Testing (MEOST) method, which was first developed by Dorian Shainin. The objective of MEOST is to cause failures, by combining stresses beyond design limits.

In this way, an effective robustness assessment could be completed quickly using very small sample sizes.

MEOST is primarily a qualitative test, but normalization of the over stress steps means that failure data can be plotted on a Weibull plot as %Stress*%Time.

This provided a semi-quantitative insight into how to maximise lifetime and reliability as part of life cycle management.

Within 3 weeks, we had identified and replicated all the failure modes that had been reported via post-market surveillance and warranty reports, as well as some new failure modes.

This has provided a wealth of knowledge, and will help ensure that the next Finger Pulse Oximeter is rugged and robust before it is approved for the market.

*Images used are generic only